ICEPP, Univ. of Tokyo, Japan

Study with the drift chamber prototype is in progress in Tokyo. The prototype has been constructed for optimizing basic parameters such as gas mixture and applied HV, and for studying the vernier pattern.

The prototype has been constructed to study operating conditions such as gas mixture and applied HV, and to investigate vernier pattern response using the same structure of the drift cell shown in the proposal. The gas mixtures used in this study were Ar:C2;H6=50:50, He:C2H6=50:50, 60:40, and 70:30. Amplification gain dependences of the anode signal on gas mixture and on applied HV were measured together with the drift velocity. The position resolutions along the direction perpendicular to the wire (x-direction) were measured by using 2.283 MeV electrons form a beta source of 90Sr. The hit position along the wire direction (z-direction) was determined in 2 steps as shown in the proposal, by the charge division method and then with vernier patterns. For designing the vernier pattern, it is quite important to confirm that the simulation predicts the ratio of observed charges by 3 pads (the left, center, and right pads). In the following sections, the experimental setup is described in Sec. 2, analysis procedures and results are in Sec. 3, and in the final section the result and a summary of this study is presented.

The prototype used in this study has a simple mechanical structure as shown in Fig. 1. It consists of 2 layers of drift cells staggered with each other by a half cell pitch as shown in Fig 2. Each layer consists of 8 drift cells that structure is presented in the proposal. The vernier foils are put on G10 plates which is sandwiched by aluminum plates where sense and potential wires are streatched. At the outermost sides of the detector, cathode foils are placed and are kept at the ground electrically.

For reading signals out from anode wires and vernier pads, preamplifiers originally developed for CDF and used in BESS experiments were employed. The details of the performance of this amplifier is reported in Ref [1]. The scheme for applying HV and preamplifier readout is schemtaticall drawn in Fig 4.

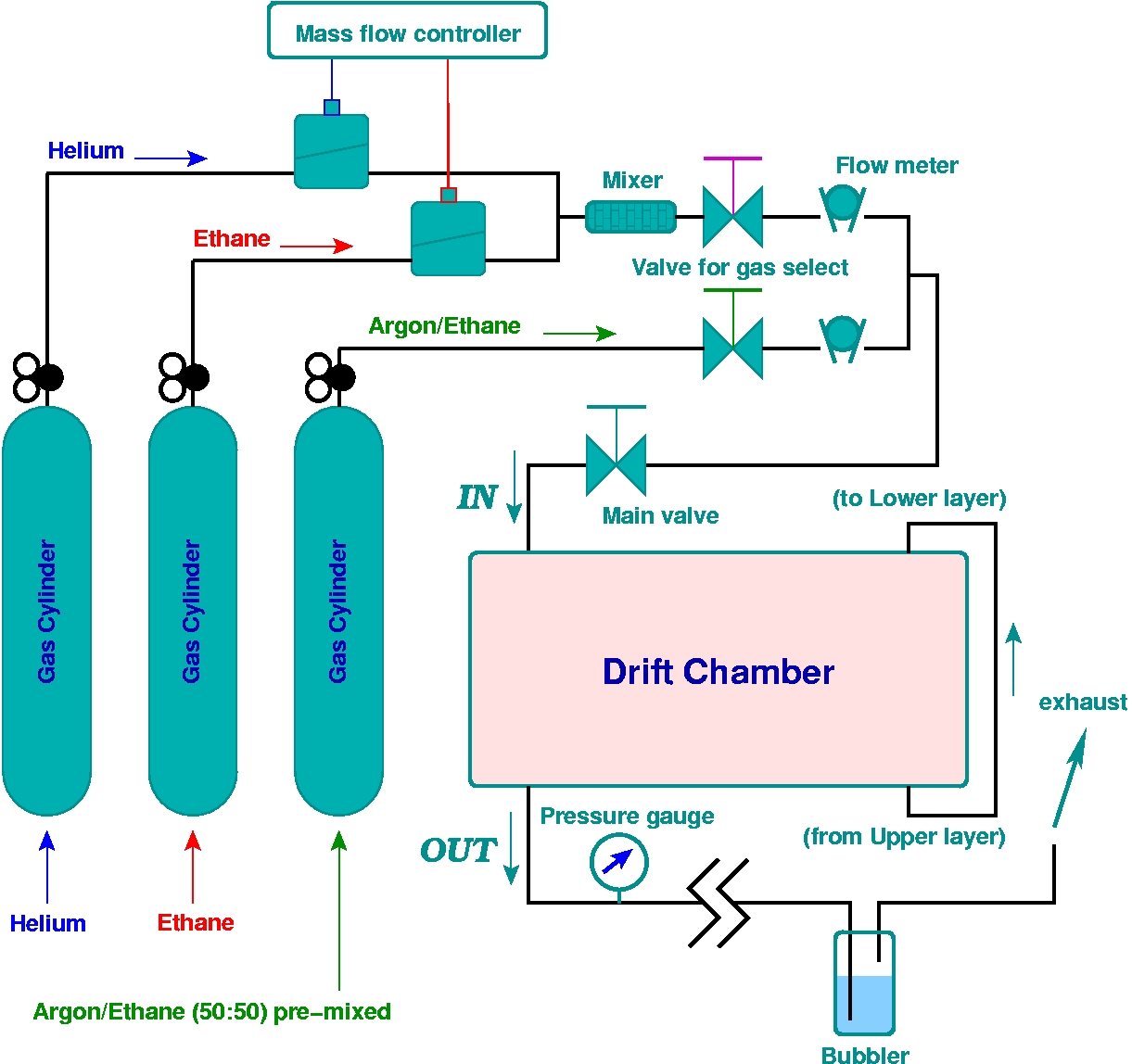

Four kinds of gas mixtures of He:C2H6=50:50, 60:40, and 70:30 and Ar:C2H6=50:50 were studied. The gas mixture was controlled by two sets of mass flow meters [2] which can controle the individual flow rate of He and C2H6 with an accuracy of 0.02 cc/min at 0° and 1 atom. Whole system to controll the gas mixture and flow is schematically presented in Fig. 9. For the gas mixture of Ar:C2H6=50:50, a bottle of pre-mixed gas was used. The inner pressure of the prototype was regulated at 1.01 atom during the study. Alarm level for the inner pressure inside the chamber was set at 1.1 atom for safety. For replacing the inner volume with any gas, the flow was continued for at least one day before the study with a flow rate of 25 cc/min.

Relative amplification gain for various conditions were measured with placing the beta source at the postion 2mm away from an anode wire. Fig. 10(left) shows the gain dependnce of the anode signal on the applied HV. It can be seen that we can obtain higher gain with larger percentge of He. Drift velocities were also measured for each gas mixture at the center of the drift cell. Fig. 10(right) shows the drift velocties for each gas mixtre as functions of applied HV. It can be seen that the drift velocities in He based gases are slower than that of Ar:C2H6=50:50, and that higher percentage of He results in slower drift velocities.

By moving the beta source in the x-direction with 1mm step, the x-t correlation was evaluated. In this procedure for determing the precise x postion in the upper (lower) layer where the particle went through, information of hit position in the lower (upper) layer was utlized taking into account the geometry of the collimator and the drift chamber. The x-t relation was updated step by ste and this iteration procedure was repeated until the x-t relations of both layers converges. Fig.11(left) shows an example of x-t relation for the gas mixture of He:C2H6=60:40 with applying 2000V on the anode wires. The distribution was fitted with a polinomial function and the residuals at positions of (a) 4.6mm, (b)3.6mm, (c)2.6mm, and (d)1.6mm from the anode wire are presented in Fig.11(right).

- position resolution on another layer used for the prediction of the hit position.

- size of the illuminated area on the anode layer.

- effect of the multiple scattering.

| Gas | Density] | Radiation Length |

|---|---|---|

| He | 0.125[g/l] | 94.32[g/cm]2 |

| Ar | 1.396[g/l] | 19.55[g/cm]2 |

| C2H6 | 0.509[g/l] | 45.47[g/cm]2 |

| Gas Mixture | Radiation Length | Multiple Scattering |

|---|---|---|

| He/C2H6(50:50) | 50.64[g/cm2] | 29.9[µm] |

| He/C2H6(60:40) | 52.84[g/cm2] | 26.2[µm] |

| He/C2H6(70:30) | 56.04[g/cm2] | 24.2[µm] |

| Ar/C2H6(50:50) | 23.08[g/cm2] | 87.1[µm] |

The second and third effects were subtructed to obtain the intrinsic position resolutions. Fig. 12 (left) shows the position resoution as a function of the distance from the anode wire for the gas mixture of He:C2H6=60:40. The best resolution was obtained around the center of the drift cell while it deteriorates to 230µm near the anode wire and ends of the drift cell. Resolution dependence on HV applied on the anode wires is summarized in Fig. 12(right) where resolutions at the center of the drift cell are plotted for different gases.

Since the vernier pattern is designed to repeat the periodic structure by 6 cm, it is required that the hit position should be estimated before analysing its signals with accuracy better than 6cm for resolving which period the hit positon belogns to. For this purpose the charge divistion technique was employed. Total charges at the both ends of anode wires were measured simultaneously with drift time. The beta source with a collimator was utilized again to study the resolution. The source and collimator was moved along the z-direction. Fig. 13 shows the reconstructed positions as a function of the source position for the gas mixture of Ar:C2H6=50:50. Fitting this relation with a liner function results in less than 2mm resolutions in sigma, which is sufficient to give predictions for the analysis of vernier pad signal.

where

- R1=(C1-C2)/(C1+C2)

- R2=(C3-C2)/(C3+C2)

| Gas Mixture | Position Resolutions |

|---|---|

| He/C2H6(50:50) | 949.9±14µm |

| He/C2H6(60:40) | 508.4±8.0µm |

| He/C2H6(70:30) | 425.4±6.9µm |

| Ar/C2H6(50:50) | 1750±43µm |

The applied voltage on anode wires was same for all gas mixtures (2000V). It is clear that increasing He percentage results in better z resolution because observed charges by each pad increases. However it shoud be mentioned that increasing He percentage could lead to higher multiplcity of anode wires due to lack of queancher. Adding small amount of iso-C4H10 or CF4 is expected to reduce the multiplicity. This effect to the track reconstruction should be studied carefully using the full simulator.

We studied the drift chamber response using a simple prototype with several gas mixtures. Signal gain, drift velocity, and position resolutions were studied for different settings of appiied HV on anode wires and gas mixture. Position resolution perpendicular to the anode wire of 93.1±10µm in simga was obtained with the gas mixtre of He:C2H6=70:30 and HV of 2000V on anode wires. We performed also systematic study on a vernier pattern using a beta source of Sr with a collimator. Using vernier pad signals position resolution of 425.4±6.9µm along the wire direction has been achieved with a gas mixture of He:C2H6=70:30. Relations between the ratios of observed charges (R1 and R2) are found to be well predicted by the simuation, which means that the simulation can be used for further optimiztion of the pattern. It was confirmed that increasing the percentage of He results in better resolution because observed charge by each pad increases. However multiplicity of hit wires in one layer for each event will also increase with higher percentage of He. In addition that will make the drift velocity slower, which is not suitable in high rate operation. This might cause unexpected problems for track reconstruction.

[1] Test of the 'Bess-Experiment' Fujitsu Preamplifiers using a Charge Injector, Oct. 2000, P.-R.Kettle

[2] KOFLEC Model-3660